- HongKong Baisite Bearing Co., Ltd

- Global drilling rig Buyer Mud pump bearings High Performance Maintenance-free Industrial Bearings Special Heavy Loading Agricultural Bearing Industry

Home> Company News> New rolling joint bearings and bearing selection

- AddressKunshan Development Zone,Tsimshatsui Kowloon Hongkong

- Factory AddressKunshan Development Zone,Tsimshatsui Kowloon Hongkong

- Worktime9:00-18:00

- Phone(Working Time)00852- 68532236

- Phone(Nonworking Time)00852- 68532236

- Fax00852- 68532237

New rolling joint bearings and bearing selection

2018-11-07 18:25:04

The joint bearing is a plain bearing and is mainly composed of an outer spherical inner ring and an inner spherical outer ring. Generally used for lower speed swinging motion, tilting motion and rotary motion. Compared with rolling bearings, it is simple in structure, small in size and large in carrying capacity. It is widely used in industrial and agricultural machinery, aerospace, mining and metallurgy, printing, textile, railway, automobile and shipbuilding. When the joint bearing works, the inner and outer rings are relatively sliding. How to effectively reduce the friction, reduce the wear and prolong the service life is the focus of research. In this paper, a new type of rolling joint bearing (hereinafter referred to as "new type of bearing") can be used to replace the traditional joint bearing to realize the oscillating motion. The rolling motion of the needle bearing is used to realize the transmission between the components of the member, which can greatly reduce the friction coefficient and reduce Wear and extend service life.

1 new bearing structure

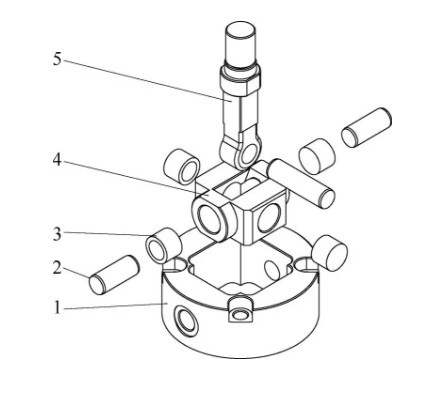

The new bearings are mainly composed of the main body, the cage, the mounting shaft, the drawn cup needle roller bearing and the shaft pin (see Figure 1). Two holes concentric on the main body cylinder are coupled to the cage structure by a shaft pin. The cage (see Figure 2) has two concentric holes on the X-axis and the Y-axis for the installation of drawn cup needle bearings. In order to reduce the turbulence during the swing and improve the swing accuracy, the four bearing mounting holes should be Distributed in the same plane; the middle V-groove design of the cage mainly considers the installation shaft to avoid the position; the mounting shaft and the cage are connected by the axle pin and the drawn outer ring rolling bearing.

2 new bearing working principle

The new bearing works in the form of oscillating motion. The principle of oscillating is that the main body is coupled with a fixed component (such as a base) by screws. The mounting shaft can swing freely within a certain range with respect to the main body, and the oscillating motion can be divided into single-axis oscillating and two-axis. swing. As shown in Fig. 3, when the mounting shaft swings around the X axis in the YOZ plane, the two needle bearings on the X axis roll, the two bearings on the Y axis are stationary, and the cage is equivalent to the main body stationary; when the mounting shaft is wound around When the Y-axis oscillates in the XOZ plane, the two needle bearings on the Y-axis roll, the two bearings on the X-axis are stationary, the cage and the mounting shaft are relatively stationary, and the cage and the mounting shaft are simultaneously swung around the Y-axis. The above two cases are called single-axis swings, and only the bearings on the X-axis or the Y-axis are individually rolled during the swing.

3 new bearing features

The new bearing structure is simple, the swinging motion process is realized by the rolling contact friction movement of the needle bearing, the rolling friction is relative to the sliding friction, the friction coefficient is low, and the service life is long; the line contact is in contact with the surface, the contact stress is large, and the rated load is low. Compared with traditional joint bearings, this new type of bearing can realize high-speed oscillating motion, featuring low friction coefficient, long service life and relatively low rated load. Needle roller bearings are the key support components for the oscillating motion. They are inexpensive and are commercially available. When the needle roller bearing wears out, it can be removed and replaced.

4 Summary

The structure of a new type of rolling joint bearing is briefly introduced. It has the characteristics of simple structure, low friction coefficient, long service life and replaceable parts. It can replace the traditional joint bearing to realize the oscillating motion.

7309BTN/DT French Guiana Bearings Angular Contact Ball Bearing 45x100x50mm

7309BTN/DT French Guiana Bearings Angular Contact Ball Bearing 45x100x50mm 29326E Tuvalu Bearings Bearing 130x225x58mm

29326E Tuvalu Bearings Bearing 130x225x58mm 22222CC/W33 uruguay Bearings 22222MB/W33 22222CA/W33 22222E Bearing

22222CC/W33 uruguay Bearings 22222MB/W33 22222CA/W33 22222E Bearing B71932-E-T-P4S Liechtenstein Bearings Bearing 160x220x28mm

B71932-E-T-P4S Liechtenstein Bearings Bearing 160x220x28mm 23036CC/W33 Lvory Coast Bearings Spherical Roller Bearing 180mmx280mm X74mm

23036CC/W33 Lvory Coast Bearings Spherical Roller Bearing 180mmx280mm X74mm